-

122025-05Huashida's One-step Equipment Sets a New Industry HighView More

-

112025-05Huashida: 3PE pipe bending technology leaderView More

-

112025-05Huashida epoxy anti-corrosion production line creates a benchmark for pipeline protection in multiple fieldsView More

-

102025-05The first shot blasting rust removal production line of Huashida was exported to UzbekistanView More

-

092025-05The Qingdao Huashida brand is gradually expanding its presence on the global stage

Since its establishment in 2003, Qingdao Huashida has weathered 21 years of challenges and growth. Through this journey, the brand has accumulated extensive experience in pipeline manufacturing, placing a strong emphasis on technological research and development, and continuously driving innovation. As a result, the company has secured multiple national patents.

View More

-

092025-05Qingdao Huashida is a well-known brand in China.

As we all know, one of the leading products of Qingdao Huashida Machinery Co., Ltd. is the PE vacuum sizing and insulation pipe production line. The Qingdao Huashida brand has earned a strong reputation in the Chinese market. Chinese President Xi Jinping once said, “We should promote the transformation from Made in China to Created in China, from China Speed to China Quality, and from China Products to China Brands.”

View More

-

082025-05HUASHIDA 1620 External Shot Blasting Line Successfully Tested, China-Russia Pipeline Cooperation Further UpgradedView More

-

082025-05High-efficiency and energy-saving solutions: Application practice of Huashida insulation pipe technology in Southeast AsiaView More

-

072025-05Engineers from Huashida went to Thailand to debug the 3PE anti-corrosion lineView More

-

072025-05Good News From Russia: Huashida's External Shot Blasting And Rust Removal Production Line Was Successfully TestedView More

-

072025-05Huashida Plan a "green energy-saving" plan for plastic machinery and plastic products

In order to implement the national strategy, Qingdao Huashida Machinery Co., Ltd. recently formulated the "Green Energy Saving Management System". The company is committed to building a resource-saving and environmentally friendly enterprise, designing green and energy-saving products, saving energy and improving energy efficiency, reducing pollutant emissions, and ensuring sustainable development.

View More

-

272025-04Application of Huashida heat shrink tape in municipal drainage pipesView More

-

262025-04What are the advantages of polyurethane spraying?View More

-

252025-04Why should the steel pipe be sprayed with epoxy powder?View More

-

242025-04Huashida double-wall corrugated pipe production line: cutting-edge technology creates a tool for pipe innovationView More

-

232025-04Huashida Xi'an colleagues start training journeyView More

-

222025-04The groundbreaking ceremony of Huashida Plant No. 7 was officially opened on March 15, 2025.View More

-

082025-04Huashida PERT pipe production line: the choice of industry innovationView More

-

072025-04Huashida water supply pipe production line shipped to Yulin, Huajian pipeline production strength further enhancedView More

-

072025-04Huashida insulation pipe equipment and 3pe steel pipe anti-corrosion equipment guard the four seasons

During the spring equinox, everything comes to life. With 21 years of industry experience, Huashida has used intelligent thermal insulation pipe equipment and 3PE steel pipe anti-corrosion equipment to draw a balanced map for modern industry to protect the four seasons.

View More

-

072025-04Huashida successfully delivered a sheet production line to a customer in Heilongjiang province ,China, deepening strategic cooperationView More

-

212025-03Huashida holds groundbreaking ceremony for plant No. 7 to build high-end plastic machinery manufacturing industrial baseView More

-

132025-03Plant a piece of new green and reap a hope - Huashida has unique sceneryView More

-

132025-03In just one month, Huashida completed the production of polyurethane spray anti-corrosion equipment for cast iron pipes with high qualityView More

-

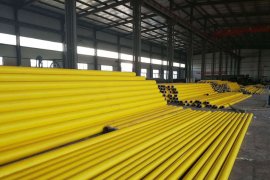

3PE Anti-corrosion coating Line

- Steel pipe inner wall sand blasting rust removal production line

- Multi-position steel pipe external epoxy (external plastic coating) anti-corrosion coating line

- Round-extrusion 3LPE coating line

- Steel pipe inside and outside epoxy powder coating anti-corrosion production line (inside and outside coating plastic, FBE) anti-corrosion production line

- Steel pipe internal and external liquid coating spraying anti-corrosion production line.

- Steel pipeline joints internal coating Robot

- Steel Pipe Outer Wall Shot Blasting line

- Steel pipe internal shot blasting line

- Steel pipe 3LPE anti-corrosion coating production line

- Steel elbow 3PE anti-corrosion production line

-

Pre-Insulated Pipe Production Line

-

Rubber Foam Insulation tube/sheet Production Line

-

Products