-

3PE Anti-corrosion coating Line

- - Steel pipe inner wall sand blasting rust removal production line

- - Multi-position steel pipe external epoxy (external plastic coating) anti-corrosion coating line

- - Round-extrusion 3LPE coating line

- - Steel pipe inside and outside epoxy powder coating anti-corrosion production line (inside and outside coating plastic, FBE) anti-corrosion production line

- - Steel pipe internal and external liquid coating spraying anti-corrosion production line.

- - Steel pipeline joints internal coating Robot

- - Steel Pipe Outer Wall Shot Blasting line

- - Steel pipe internal shot blasting line

- - Steel pipe 3LPE anti-corrosion coating production line

- - Steel elbow 3PE anti-corrosion production line

-

Pre-Insulated Pipe Production Line

-

Rubber Foam Insulation tube/sheet Production Line

-

PE PP Sheet/film/Board Extrusion Line

- - Water-proof Coiled Material /GEO-membrane Film Extrusion Line

- - PE/PP/PS/HIPS/ABS Single extrusion & Multi-layer Sheet Co-Extrusion Line

- - Adhesive coating line of heat shrinkable sleeve

- - Fibre reinforced 3-layer PE cross-linked heat shrinkable sleeve backing film production line

- - PE Carbon Fibre Spiral Pipe Extrusion Line

- - PE PP Sheet/Board Extrusion Line

- - Electro-fusion girth welding joint closure production line

- - Heat Shrinkable Sleeve extrusion and Coating Line

-

Pipe Fittings

-

HDPE pipe production line

-

HDPE/PP Double Wall Corrugated Pipe Production Line

-

HDPE Hollow Wall Corrugated Pipe/ Structured Wall Pipe Extrusion Line

The vacuum calibration polyurethane insulation pipe is a kind of high efficiency pre insulated pipe. It is mainly composed of working steel pipe, PU insulation layer, plastic outer protective pipe and other parts.

- introduction

- Features

- Technical parameters

- advantages

- Application scenarios

- Inquiry now

- Related products

The working steel pipe is in the innermost layer and assumes the conveying medium(For example: hot water, steam) function. In the middle there is a PU insulation layer, playing the role of heat preservation and insulation, which can effectively reduce heat loss. The outermost layer is a plastic outer protective tube, usually made of materials such as high-density PE. It can protect the insulation layer from the external environment erosion, but also make the pipe appearance more regular.

|  |  |

Main Extruder Structural features: high strength, wear resistance, corrosion resistance, good screw plasticization effect; The temperature control system adopts ceramic heating coils for heating and fan cooling, and uses temperature sensors, temperature controllers, etc. for automatic temperature control. | Control system Adopting Siemens PLC centralized control and unique DCL software design. Implemented interoperability between systems, windows, and human-machine interfaces, endowing machines with AI intelligence and simple operation. Save labor and effort, with no safety hazards. | Planetary cutting machine By using the Haff block planetary cutting machine, it can ensure that the cutting section is vertical and neat, without the need for secondary processing. Adding a powder collection system can ensure a clean and tidy production site. |

|  |  |

| Jacket Extrusion Line | Polyurethane foaming system | Threading platform |

960MM whole machine complete machine

Extrusion Machine traction machine

Internal structure of tractor cutting machine cutting machine

Vacuum sizing box mold

Head mold Extrusion unit

Thermal insulation pipe

Production line parameter:

(1)Steel pipe range:60mm-2000mm

(2)Used material:ISO(isocyanate), POLY(premixed polyether polyols),PE

(3)Main equipment:extruding machine,extrusion die model, vacuum calibration tank,Haul off machine,cooling equipment,cutting equipment,polyurethane foaming system、pipe assembly platform, etc.

| Model | Host model | Pipe specifications | production capacity | Total installed capacity | Production line length |

| PE-110-550 | SJ-75/33 | 110-∮550mm | 250-350kg/h | 160KW | 34M |

| PE-450/960 | SJ-90/33 | ∮450-∮960mm | 400-600kg/h | 380kw | 36m |

| PE-850/1380 | SJ-120/33 | ∮850-∮1380mm | 700-900kg/h | 440kw | 40m |

| PE-960/1680 | SJ-150/33 | ∮960-∮1680mm | 1200-1300kg/h | 580kw | 48m |

| PE-1155/2000 | SJ-120/38 | ∮1155-∮2000mm | 1200-1600kg/h | 560kw | 48m |

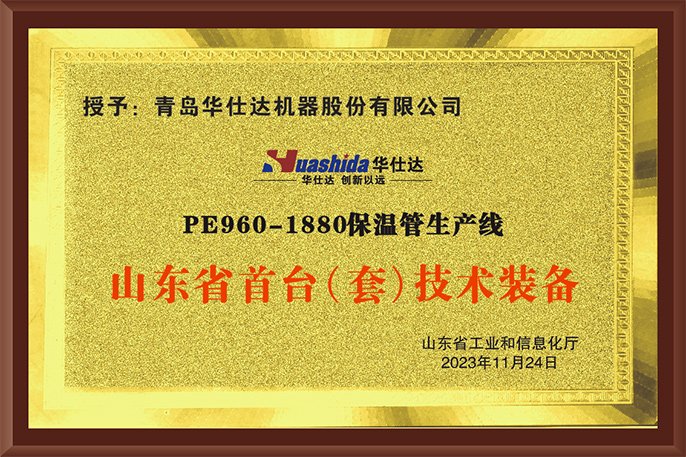

01 Awarded the first (set) technical equipment in Shandong Province

02 High speed, high efficiency, stable and reliable.

03 Provide complete production equipment for over 400 enterprises

04 Provide 24-hour response service to solve customer concerns and difficulties

05 70% customer repurchase rate, making Huashida a highly recognized brand by customers

06 The equipment is sold to countries and regions such as Europe, America, the Middle East, Central Asia, Africa, Russia, etc